About the IAMFat Project

Intelligent Additive Manufacturing for improved Fatigue strength of welded connections

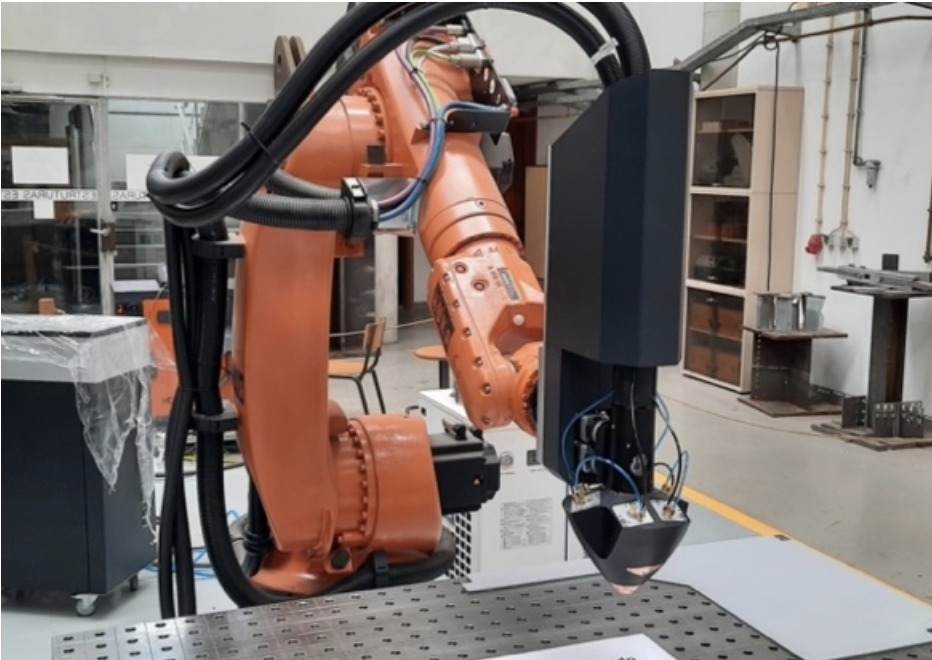

As an alternative to the conventional steel fabrication processes, additive manufacturing (AM) of steel is rapidly gaining popularity due to the free-form capabilities for the optimal use of material and flexibility in adapting a fabrication procedure to the shape and expected volume of the additive material. Among the different AM processes, the most suitable for large-scale parts and serial production, in terms of speed and accuracy of use, is wire and arc additive manufacturing (WAAM). The WAAM fabricated parts undergo fast cooling, which may result in internal defects and/or non-homogeneous material properties. This has an important influence primarily on the strength of the structural component, residual stresses and distortions. These challenges are even more important in the case of fatigue-sensitive applications.

The intelligent design of such critical structural details, in steel bridges, hollow section joints of offshore supporting structures and demanding details of roller-coaster structural parts enables the material and possibly cost savings. The project is conceived in three main parts in which an experimental program is combined with advanced numerical simulations predicting behaviour of structural components at different scales:

- i) establishment of generic material testing for basic structural components 1D, 2D and 3D WAAM components which will provide basis for standardization of WAAM material;

- ii) small-scale structural components exposed to fatigue;

- iii) feasibility and structural testing of the full-scale application using WAAM as a possible method for improvements in structural performance.

IAMFat

Project objectives

To establish an innovative strengthening process by combining hot-rolled steel material and WAAM in a cost-effective way.

To introduce hybrid numerical and data-driven models of the manufacturing process by optimizing fabrication tolerances, fabrication time and fit-for-purpose mechanical characteristics.

To provide enhanced fatigue life by optimizing the manufacturing process for improved material properties.

To establish the basis for certifying WAAM parts based on non-destructive testing techniques.